Results

The Objective:

To develop a breakthrough innovation compared to the actual steel production process bringing together steel making with electrochemical process. It transforms iron oxide into steel plate with a significant reduction of energy use.

Main Results:

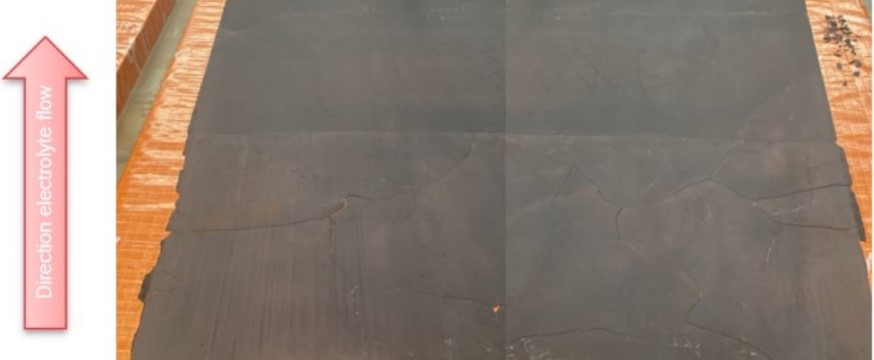

- SIDERWIN pilot plant has been built and its able to produce iron plates.

- The average metallic iron content was found to be around 96% and can be up to 98.7% under stable working conditions, the magnetite content was less than 4%.

- It is possible to reach high faradaic yield, close to 90%, under stable working conditions.

The benefits:

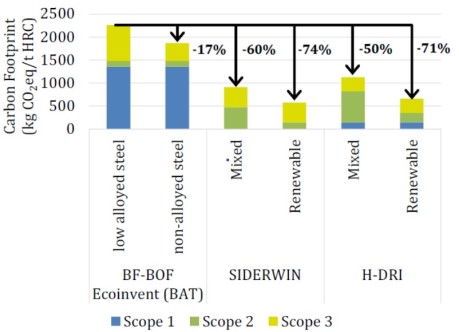

SIDERWIN and the H-DRI technology perform better in term of carbon footprint than the currently used BF-BOF. For the SIDERWIN technology with DSR, mixed, the carbon footprint amounts to 0.9.t.CO2eq which is 60% lower than the BF-BOF technology. With the renewable electricity mix, the total carbon footprint is 0.6 t CO2eq which is a reduction of 74%. The H-DRI technology has a similar carbon footprint than SIDERWIN with 1.1.t.CO2eq with DSR, mixed and 0.7.t.CO2eq with DSR, renewable, which represent reductions of 50% and 71%, respectively.

Main Conclusions:

- SIDERWIN technology can contribute to future carbon neutral steelmaking with:

- Almost no direct CO2 emissions.

- At least -60% carbon footprint vs traditional BF-BOF route.

- Without compromising environmental footprint vs BF-BOF route.

- Fully electrified primary production.

- The pilot technical performances have been validated and optimal parameters for operation have been defined, the SIDERWIN technology has been successfully scaled up. The main results obtained from the pilot trials are:

- It is possible to use cathode with size up to 1.25 m².

- Electrolysis cell energy use confirmed at pilot scale have demonstrated that the 2.7 MWh/t of Fe produced are reachable in optimized conditions.

- The SIDERWIN technology can contribute to the balance of the power system with its fully electrified steel primary production. The European power system can meet the additional SIDERWIN demand with carbon free means.

- The SIDERWIN technology can contribute to circular economy, via the possible integration of raw materials.

The Future:

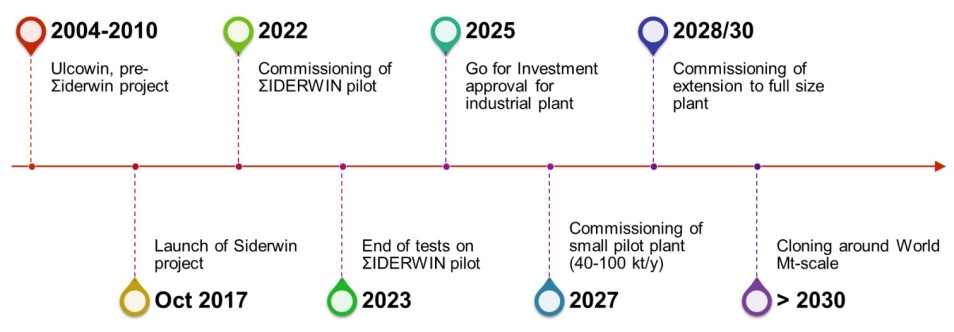

Based on the results of the project a roadmap for the industrialization and development of the technology has been defined. The history of the development of this technology and the future industrialization forecast is shown in the image below.